2025 Redeemer Wheat Berries Available

No Minimum Order, Price $1.50 Per Pound

The University of Vermont Grain Testing Laboratory shows our 2025 Redeemer wheat to have excellent baking qualities. Reach out to mail@whitesfieldsfarm.com for packaging and delivery options such as UPS or USPS shipping, or pick up in Hardwick, MA, Codman Community Farms at 58 Codman Rd, Lincoln, MA, or Burlington, MA. Abbie sells grain at the Hardwick Farmers Market on the Hardwick Common 01037 on Sundays from 11-2 in the fall. We recommend cool and dry storage of our grain.

2025 Redeemer Wheat Berries Specs

Redeemer_Wheat_2025_UVM (pdf)

Download2023 Hazlet Rye Berries for Sale

Rye Berries for Sale

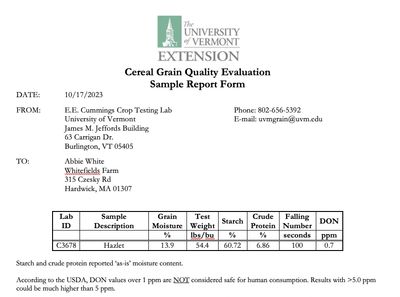

Cost $1.25 per pound for 2023 Hazlet rye berries with no minimum amount. Reach out to mail@whitesfieldsfarm.com for packaging and delivery options such as UPS or USPS shipping, or pick up in Hardwick, MA, Codman Community Farms at 58 Codman Rd, Lincoln, MA, or Burlington, MA. We recommend cool and dry storage of our grain. Rye recipes

Grain Testing and Baker Feedback

Baker feedback has been positive with loyal customers. We are confident that you will be happy with our Redeemer Wheat Berries for use with your grain mill. A baker's perspective: "We baked with your Redeemer last week and it was fantastic. We made a sourdough loaf with 100% whole grain Whitesfields Farm Redeemer. It took 105% water and could have taken more. It felt great throughout the whole process and baked up beautiful. You should feel 100% confident that you have a superior bread wheat."

Supporting Brooklyn Granary & Mill 10/29/2024

Patrick Shaw-Kitch is a loyal and supportive buyer of our grains

We are thankful to be asked to support the Kickstarter campaign for launching the Brooklyn Granary & Mill. The Miller, Baker, and Owner, Patrick Shaw-Kitch has been a wonderful supportive and loyal buyer of our grains. We want his great endeavor to succeed and benefit many small grain growers who practice sustainable agriculture. https://www.kickstarter.com/projects/brooklyngranary-mill/brooklyn-granary-and-mill

Shown in the image is bread baked entirely with our Redeemer wheat

2023 Grain Testing Results

Growing and Harvesting Videos

The image to the right shows our best field of Redeemer field with our combine harvesting equipment.

Video of 7/24/21 wheat field harvest

Wheat

Background and History

Our milling building grinds and sifts flour all year round. Our customers receive freshly prepared flour. Milling is not our full time occupation and so visits to our farm and milling building are best done by appointment. We are strong supporters of local farming. Please reach out to us if you are interested in seeing what we do in terms of growing, harvesting, storage, grinding, and sifting wheat. My family wants to see other farms succeed with growing grains. Rotational grazing with pastured animals combined with grain sowing is a sustainable agricultural practice. We can explain and show you in detail what has worked for us. E-mail us at mail@whitesfieldsfarm.com or text 413 813 8205. View our video below from May 11, 2019 showing our pasture/grain fields.

The local food movement continues to thrive and expand in our communities. Growing wheat in Hardwick in recent years has been both a fulfilling family and community activity. The co-existence of grazing animals and grain production works well with our farmland.

In 2010, Stan came up with the hobby idea of “The 1000 yard beer project” where all the ingredients would be sourced near our house. I had already thriving hop vines and he decided to grow a field of barley. The barley plants ended up looking awful at harvest time and so the crop was abandoned for the wild turkeys to eat. However, our interest in grain growing was firmly planted. From many conversations we understood that if we could produce grain, then our local community would support us with markets.

Next year’s effort led to growing barley as well as the ancient grains, Emmer and Red Fife. For our first harvest we dried a wagon load of scythed wheat and then stuffed this in large burlap bags. With friends, we beat the bags hard with nunchucks. A powerful fan blew away the chaff from the heavier seed. We ended up with a yield of 50 pounds of wheat from having planted 50 pounds amount of seed. This was an entertaining learning experience with lots of beer drinking.

We realized that growing wheat is as easy as planting grass. After harvest, we return the field to pasture for our grazing animals for at least three years to build up fertility and reduce weed pressures. With our wheat field rotation, there is natural weed suppression. Animal grazed and fertilized pastures results in little worry that weeds will diminish yields and taint the grain quality in terms of taste and purity.

As my family became more ambitious with growing grains, we understood that we needed more practical methods for threshing and winnowing. Our next step in 2012 was to attend University of Vermont sponsored grain growing events. We toured Ben Gleason’s wheat fields and milling operation and decided to follow the model of his small scale one man operation. His hard red winter wheat variety bread in Canada, Redeemer, ranks high in taste tests. Ben helped us obtain our Redeemer wheat seed for the first three years. We now save our own seed. As the continue to plant and save seed, our grain will adapt and change for our Hardwick climate. Down the road, we will be growing a truly local wheat variety.

For harvesting and threshing we bought a small-scale combine for rice and wheat from China. For winnowing, Stan purchased a 100 year old clipper mill from Kansas. My son's engineering expertise helped turn this antique into a completely functional machine. We were thrilled when our Redeemer wheat tested at the UVM Grain Laboratory as a high quality crop in September 2012. With some trepidation, we offered a sample to Glenn Mitchell at Rose32 Bakery in Gilbertville. We were ecstatic with his positive feedback and strong encouragement. We have a great relationship with bakers, that continues to expand.

For 2015, we produced 8000 pounds of Redeemer wheat. We used a renovated 1959 Allis-Chalmers combine to bring the entire crop in on one day before a thunderstorm.

Packages of our flour and wheat berries are sold by Stillman’s Farm. Elmendorf Baking Supplies & Cafe in Cambridge mills our wheat berries upon customer request.

My oldest son built a timber frame structure with the use of his sawmill to house an Austrian manufactured Osttiroler Getreidemühlen stone mill. This mill makes it possible for us to supply larger volumes of high quality flour to bakeries like Rose32. A large sifter from North Carolina removes bran to make a bolted flour. Bolted flour has the nutrition and flavor of whole wheat without the heavy and high water absorption qualities.

Wheat Growing and Sheep Grazing

Our fields on May 11, 2019

Combining Wheat History

The 2018 wheat harvest was difficult. A few days before combining on July 20th, a storm a thunderstorm with high winds damaged the crop. The flattened areas represent lodged plants. You see Stan with the 1959 Allis-Chalmers combine ride over these plant stalks. Thankfully, most of the wheat could be harvested. Our wheat berries passed all quality parameters at the University of Vermont Grain Testing Laboratory.

Scything and Combining Wheat 2016

Scything is great exercise and requires no fossil fuel, but....